Файл: Реферат Выпускная квалификационная работа содержит 5 глав, написанных в 106.docx

Добавлен: 28.03.2024

Просмотров: 43

Скачиваний: 0

ВНИМАНИЕ! Если данный файл нарушает Ваши авторские права, то обязательно сообщите нам.

СОДЕРЖАНИЕ

Процессы старения в полимерных диэлектриках

Влияние частичных разрядов на старение полимерных диэлектриков

Выбор формы образцов и электродов

Выбор методики проведения испытаний

Меры по технике безопасности [5]

Определение кратковременного пробивного напряжения

Анализ и обсуждение экспериментальных данных

Оценка возможности использования термофлуктуационной теории для анализа полученных результатов

The structure and volume of work

Chеmical аnd Electroсhemical Deteriоration аnd Breakdоwn

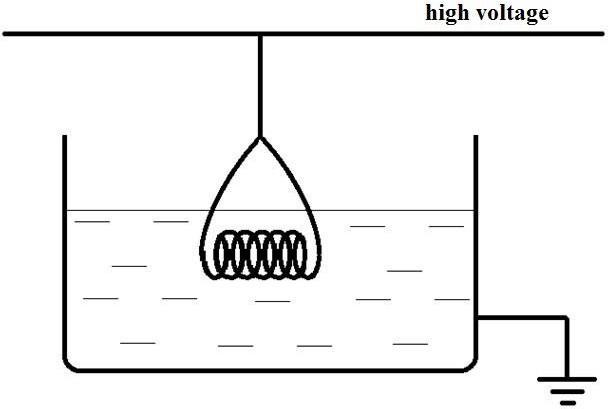

tested for breakdown voltage in alternating current frequency of 50 Hz in water, on a high- voltage installation is shown in Fig.7 in accordance with GOST 2990-78.

Test 10 groups of samples of wires for 5 samples in each group. To create the most rigid test conditions that mimic operating conditions, samples of pre- wound wire placed in a heat chamber and kept at a temperature of 250 .

Removing any groups of samples was every two days, and then were tested to determine the short-term breakdown voltage (Fig.2.).

Fig.2. The definition of short-time breakdown voltage insulation wire specimens after exposure to elevated temperatures

The results of tests on the breakdown voltage of samples of wires with a solid polyimide insulation are given in table 1.

Table 1 – test Results for breakdown voltage in the initial state and after exposure to a temperature of 250

The results obtained by changing the breakdown voltage wiring patterns with a solid polyimide insulation can determine the average short-term breakdown voltage of 12.3 kV.

set the desired temperature aging (Fig.2.)

Fig.2. General view of the samples placed in a heat chamber

It should be noted that each successive batch of samples is laid at another temperature to eventually evaluate the effect of temperature on the time to breakdown. Once a breakdown occurs, the time is recorded. The test results are shown in Table 1.

Table 1 – The test results for up to breakdown

From the outcome of our investigation it is possible to conclude that the results will be used in design, production and operation of polyimide insulated wires and cables.

Test 10 groups of samples of wires for 5 samples in each group. To create the most rigid test conditions that mimic operating conditions, samples of pre- wound wire placed in a heat chamber and kept at a temperature of 250 .

Removing any groups of samples was every two days, and then were tested to determine the short-term breakdown voltage (Fig.2.).

Fig.2. The definition of short-time breakdown voltage insulation wire specimens after exposure to elevated temperatures

The results of tests on the breakdown voltage of samples of wires with a solid polyimide insulation are given in table 1.

Table 1 – test Results for breakdown voltage in the initial state and after exposure to a temperature of 250

| Т, | n, number of samples | t, h | a Breakdown voltage of polyimide isolation (average value), kV |

| in the initial state | 5 | 0 | 14,8 |

| 250 | 5 | 72 | 13,4 |

| 5 | 96 | 14,2 | |

| 5 | 144 | 12,6 | |

| 5 | 240 | 11,8 | |

| 5 | 288 | 12,7 | |

| 5 | 336 | 12,5 | |

| 5 | 482 | 11,6 | |

| 5 | 578 | 11 | |

| 5 | 674 | 11,3 | |

| Average: | | | 12.3 |

The results obtained by changing the breakdown voltage wiring patterns with a solid polyimide insulation can determine the average short-term breakdown voltage of 12.3 kV.

-

Description of the experimental results on time before breakdown On the basis of the previous section 3.1., we chose the level of the test voltage - 9, 7 kW. The temperature selected for conducting tests: 80, 100, 120,140,150. Then the samples of the first batch are placed in a heat chamber, we

set the desired temperature aging (Fig.2.)

Fig.2. General view of the samples placed in a heat chamber

It should be noted that each successive batch of samples is laid at another temperature to eventually evaluate the effect of temperature on the time to breakdown. Once a breakdown occurs, the time is recorded. The test results are shown in Table 1.

Table 1 – The test results for up to breakdown

| Upr, kV | 9 kV | 7 kV | |||||

| Т,°С | 80 | 100 | 120 | 140 | 150 | 100 | |

| t, с | 11,6·103 | 8,1·103 | 8,5·103 | 4,3·103 | 6·103 | 21,8·103 | |

| | 11,8·103 | 9,8·103 | 12,9·103 | 6,1·103 | 7,3·103 | 24,9·103 | |

| | 12·103 | 10,9·103 | 13,1·103 | 7,2·103 | 9,9·103 | 25,3·103 | |

| | 12,9·103 | 11,2·103 | 14,3·103 | 12,3·103 | 10,3·103 | 26·103 | |

| | 13,2·103 | 11,9·103 | 14,9·103 | 13,9·103 | 13,5·103 | 27,2·103 | |

| | 13,3·103 | 12·103 | 15,5·103 | 14,1·103 | 15,9·103 | 27,4·103 | |

| | 13,7·103 | 13,5·103 | 19,1·103 | 16,1·103 | 16·103 | 30,2·103 | |

| | 13,8·103 | 13,6·103 | 19,3·103 | 16,4·103 | 18,4·103 | 31,1·103 | |

| | 14,1·103 | 14,8·103 | 19,5·103 | 16,8·103 | 18,5·103 | 34,7·103 | |

| | 14,3·103 | 15,6·103 | 19,9·103 | 18,1·103 | 19·103 | 35,7·103 | |

| | | | 21,1·103 | 20,8·103 | 20·103 | | |

| | | | 23,2·103 | 21,8·103 | 21·103 | | |

| | | | 23,8·103 | 23,7·103 | 23,5·103 | | |

| | | | 24,8·103 | 24,6·103 | 24,4·103 | | |

| | | | 25,7·103 | 25,1·103 | 24,6·103 | | |

| τср, с | 1,307·104 | 1,214·104 | 1,837·109 | 1,609·104 | 1,625·104 | 2,4·104 | |

Conclusion

From the outcome of our investigation it is possible to conclude that the results will be used in design, production and operation of polyimide insulated wires and cables.